Consumers today are already familiar with personalizing their favorite treats by molding them into unique shapes or printing edible messages on cakes, chocolate and flowers, among others. What if you could customize any product in the future to suit your preference – from shoes to even houses? While some may perceive this to be a pipe dream, the fact is that this is actually a reality. New Balance just introduced 3D printed shoes last April, and in China, Huashang Tengda successfully built a two-storey house in just under two days!

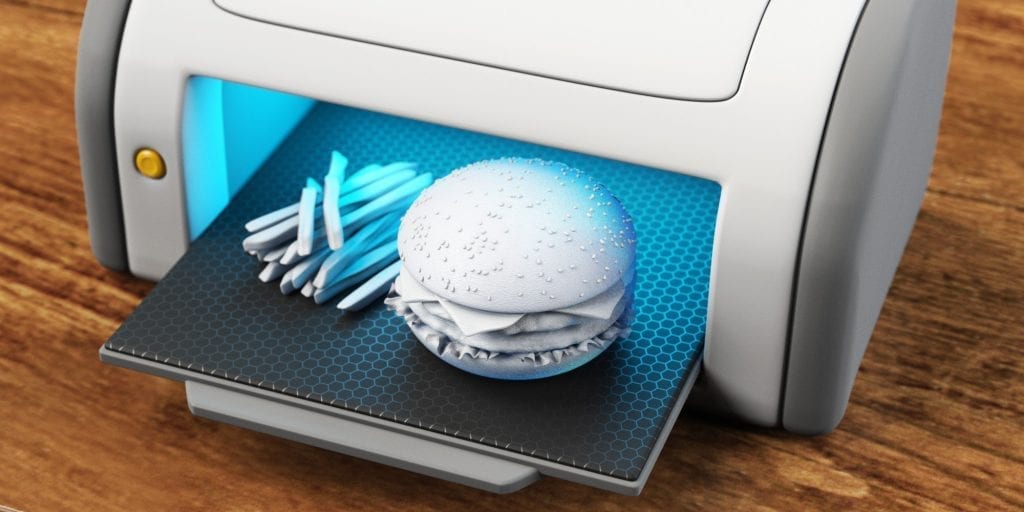

3D printing is also known as additive manufacturing, a process that allows us to seemingly create objects such as bicycle frames and toys out of thin air. Manufacturing and supply chains have typically been all about assembly lines, warehousing and shifting products outwards from the point of manufacture. 3D printing is now revolutionizing the way products are manufactured and distributed.

With the advent of 3D printing, individualized products can be designed, produced, delivered, and serviced in new ways. To start, organizations can leverage a product innovation platform that supports direct communication with customers and network partners from conceptualization to production. Consumers today love to customize everything and anything, and 3D printing makes this both possible and affordable. Organizations can now evolve beyond demand-driven supply chains to enable demand-driven manufacturing, furthering customer centricity and personalization.

3D printing is also transforming the manufacturing industry, making it more digitized and in the process throwing out all the traditional rules of the game. Essentially, 3D printing changes who is in control. Analog manufacturing used to be the realm of huge companies that have the resources to invest and produce large quantities of the same good. These companies need to have the capital to support research, prototyping and focus groups to identify products that will please the critical mass, and marketing to promote that same product to large volumes of consumers. On top of that, delivering the products to consumers requires complex supply chain and retail channels.

In contrast, 3D printing allows complex items to be produced on demand, eliminating the need for assembly lines. With 3D printing, the supply chain has the potential to become more efficient, more local and globally connected. Manufacturers are using 3D to respond to dynamic, real-time customer demands, reduce inventory and slice into transportation costs while dramatically compressing the time needed to ship products.

Imagine this: Without the need for huge capital outlay, manufacturers do not need to set up factories at permanent locations. All manufacturers need is a 3D printer in local markets or regional production hubs, solving a number of large problems. The ability to bring manufacturing local will provide a way to significantly reduce carbon footprint. If you add the benefits of timeliness, cost reduction, and the freedom to print multiple materials and properties, you start to understand the impact 3D printing can have on society.

Supply chains have a reputation for being boring, complicated, and uninteresting. But with the advent of the digital economy and 3D printing technologies, all of this is about to change. As the digital supply chains become both disruptive and important within the next few years, supporting the supply chain and the manufacturing floor to boost productivity will have ripple effects throughout any industry. The future of supply chain will be more collaborative and integrated with suppliers, retailers and even product planning and design.

Where supply chain used to be the most inelastic piece in the journey from manufacturing to customer delivery, 3D printing will be the catalyst and enabler to reimagine a supply chain that can dynamically respond to customer requirements and expectations. In addition, we are going to see more of these advanced efficiencies permeating production activities as 3D printing continues to rise past the hype and into everyday manufacturing.

In 2013, Wohlers Associates, a consulting firm that specializes in 3D printing, predicted that the sector would grow to $10.8 billion by 2021. The firm now forecasts even greater and faster growth, with the industry reaching $21.2 billion in 2020. That’s because while the firm is skeptical about the value of low-end, consumer-oriented printers, they are positive that more and more industrial clients – especially manufacturers – will be buying and implementing high-end, expensive 3D printers.