Amid ongoing trade tensions and economic uncertainties, Apple is exploring the possibility of relocating its iPhone manufacturing to the United States. However, significant advancements in robotics are crucial to making this ambitious goal a reality, according to Commerce Secretary Howard Lutnick.

Vision for American Manufacturing

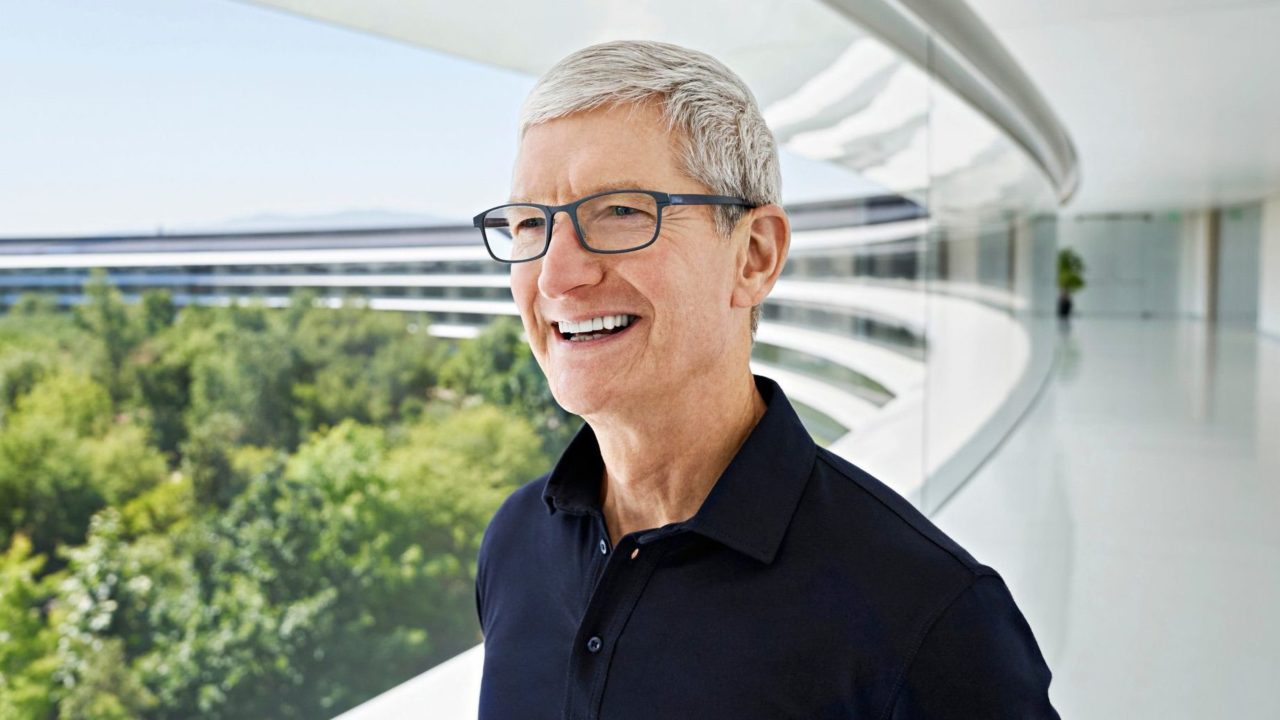

During a recent CNBC appearance, Lutnick shared insights from Apple CEO Tim Cook, who identified a “key catalyst” necessary for the tech giant to begin assembling iPhones domestically. Specifically, Cook indicated that state-of-the-art robotic capabilities at scale and precision would be vital for any U.S.-based production lines.

The Role of Automation

By leveraging robotics for assembly tasks traditionally met by low-wage laborers in countries like China, Apple can better manage labor costs and maintain competitive pricing. Currently, assembly workers in Shenzhen earn between $3 to $3.70 per hour, whereas meeting the U.S. federal minimum wage of $7.25 would significantly escalate production costs.

Utilizing robots in the manufacturing process may not only reduce costs but also enable potential price reductions for the iPhone—benefits that could resonate deeply with consumers.

A Long Road Ahead

While the vision of a robotic assembly line is compelling, practical implementation remains distant. Lutnick acknowledged this challenge, suggesting that technological advancements will require time for effective integration. The prospect of U.S.-based manufacturing hinges on the development of robotics that can efficiently handle the intricate assembly processes of complex devices.

Commitment from Leadership

Insisting on the feasibility of this transition, Lutnick claimed, “Tim Cook wants to build it here, and he will build it here.” However, the discussion leaves unanswered questions regarding the workforce dynamics in these potential factories. While American workers may oversee operations, the specifics of who will handle assembly remain unclear.

Looking Ahead

The administration’s support for advanced manufacturing technologies could position the U.S. as a leader in innovative production practices. If allowed the time and resources to advance, this initiative could redefine the landscape of American manufacturing and elevate consumer electronics production standards. As the dialogue around U.S. manufacturing evolves, both consumers and the retail sector are poised for significant change.